Product Detail

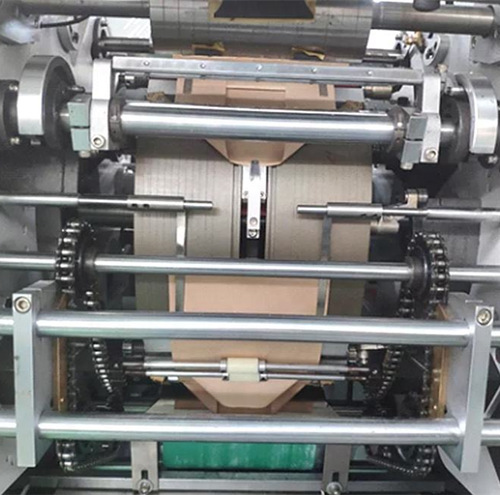

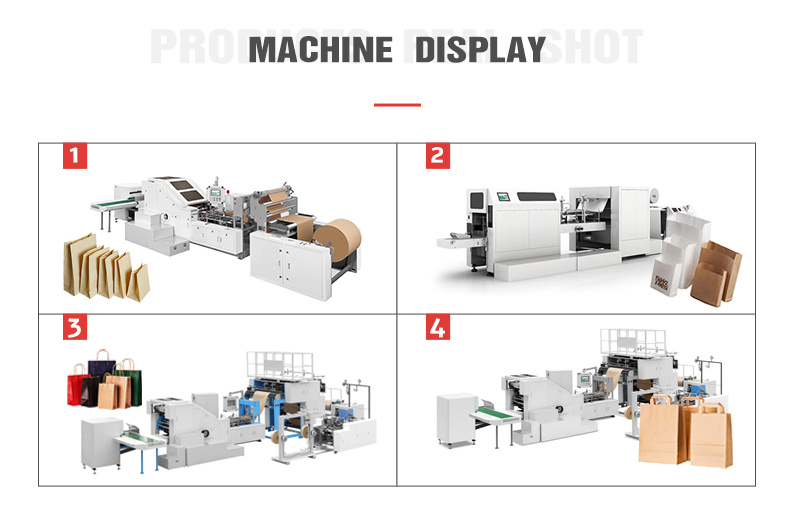

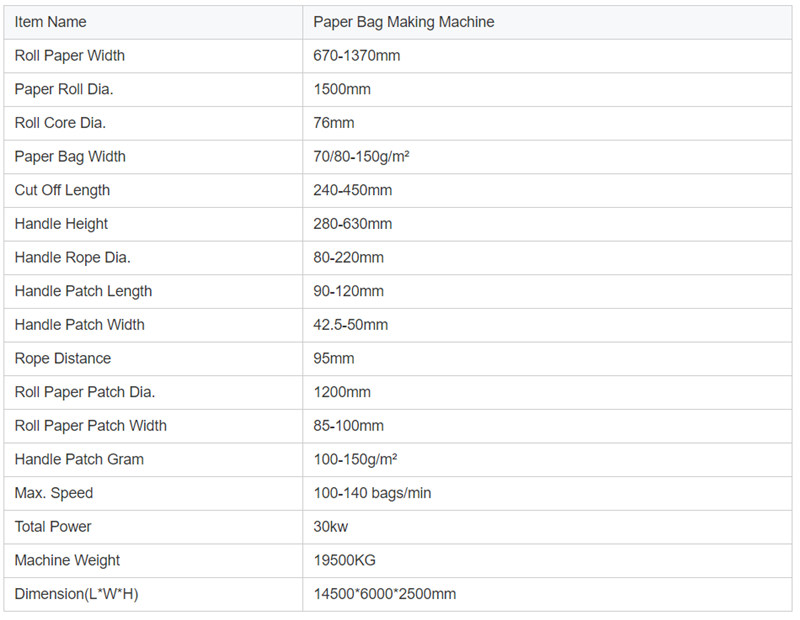

Automatic high speed paper bag forming machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper,medico paper and so on, bag making process consist of puncture, side gluing,sidefolding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in onetime. Our machine have advantage of easy operation, high effeciency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment friendly paper bag.

Product Features:

1. The man-machine interface of Weilun touch screen is adopted, the operation function is clear at a glance, easy to control.

2. Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability.

3. Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size.

4. The loading and unloading of raw material adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic

constant tension control.

5. Brushless servo motor is used to correct the deviation of raw material and reduce the adjustment time of paper roll alignment.

After-sales service

Your worker will have 3-5 days free training in our factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

Our company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. Our packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customes port without a hitch in 40 working days.

Q:What is your Installation Services?

Installation Services are available with all new machine purchases.

We will provide the user manual and videos to support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

Q:What about your Guarantee of quality?

The machine is 1 year warranty, all machine part can be replaced for free within 1year if broken(not including man made).And offer lifetime after sale service

Q:How about the after-sale service?

(1)More than 12 hours after-sale online service one day.

(2) we have engineers available to service machinery overseas.The service charge, include: service fee USD100/day, VISA fee, board round-trip ticket, room and eat in are buyer’s side.

Q: How about the spare parts?

After we deal down all the things , we will offer you a spare parts list for your reference.

Q:If we have very special request for the production line, could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q: If we have samples of new products, can you help to analysis and design the machine?

Yes, Our technical department can help to analysis, design and test the new products you offered.

Q: What can you buy from us?

Paper Straw Production Line,Slitter Machine,Packing Machine: Extrusion Machine,Recycling Machine,Packing Machine,Extrusion Machine.