Introduction:

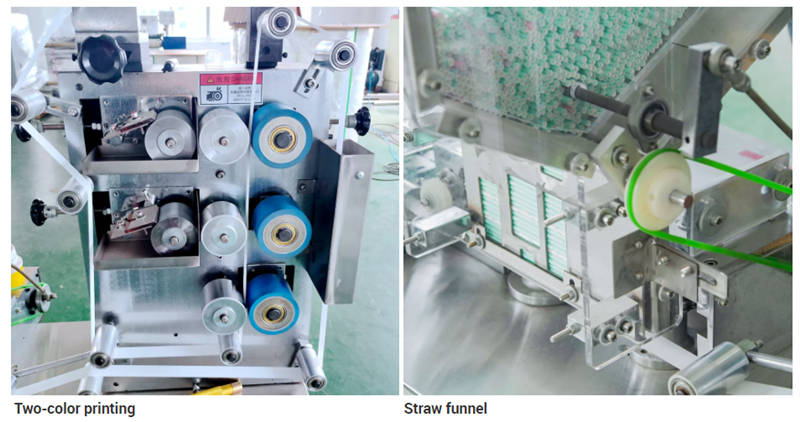

PP plastic drinking straw making machine uses polypropylene (PP) as raw materials, with the use of masterbatch, after melting, extrusion, shaping, cooling, pulling, cutting, then produce drink straws. It is composed of main body, tooling, water cooling system and cutting machine.With a variety of models such as single color, two-color, three-color straw extrusion line options.

Characteristics:

Characteristics:

1.Widely used: straws, sugar sticks, cotton swabs, air clubs and small PE tubes ;

2.Diversified in cut-end:90°、45°、60°;

3.Screw and barrel is made of 38CrNoAl material and had nitrogen treatment;

4.304 food grade stainless steel hopper,cover and water cooling tank; spray-paint treatment on machine case;

5.Control panel concise designed for easy operation.

Characteristics:

Characteristics:

Quality Throughout:

Quality Throughout: